Fangli Electric Motors' Remarkable Presence

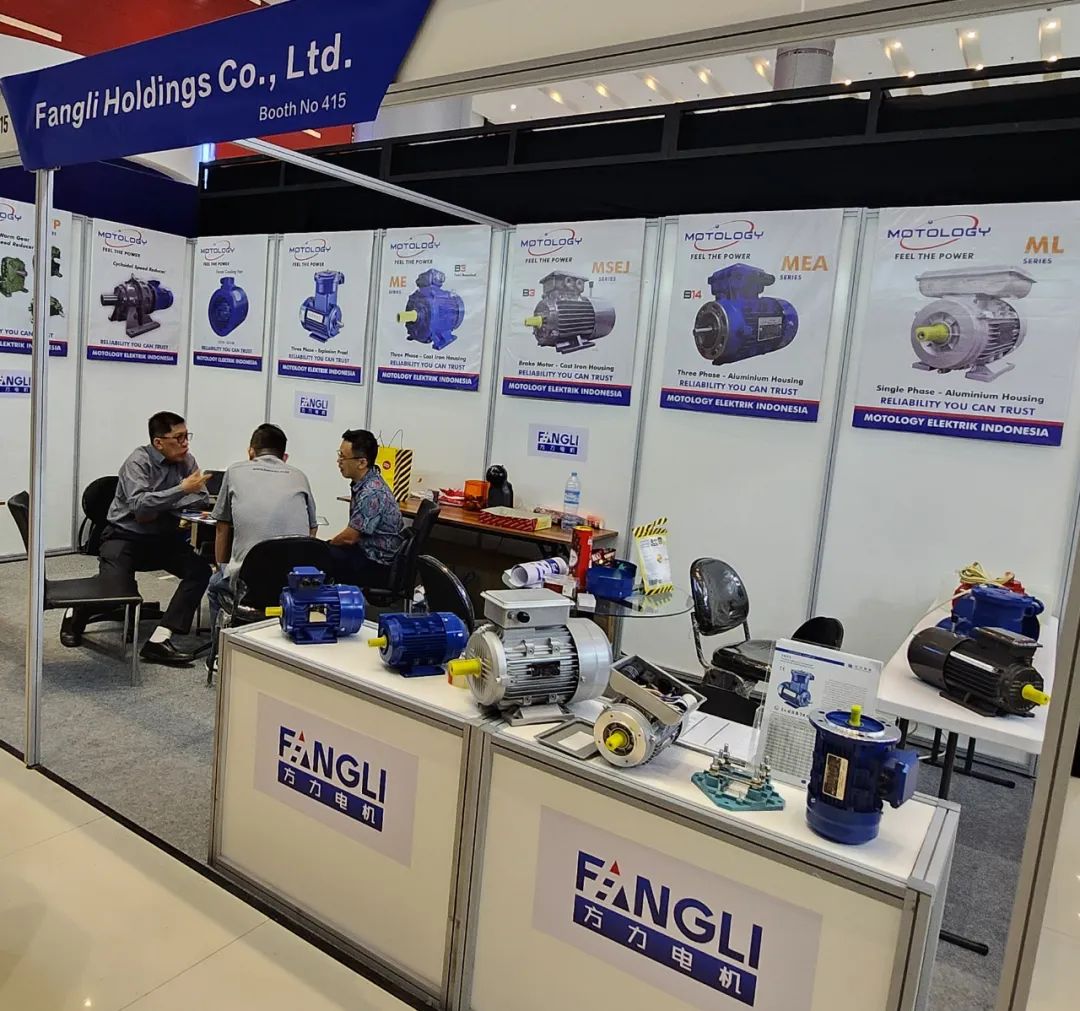

Fangli Electric Motor was honored to participate in this exhibition, with Booth 415 becoming one of the focal points of the event.

On-site, Fangli Electric Motor showcased a variety of product series, attracting a large number of visitors for exploration, inquiries, and exchanges.

The main products Fangli Motors exhibited during this event included:

FL3 High-Efficiency Motor Series: The FL3 (IE3) series is an environmentally friendly, high-efficiency motor known for its energy-saving capabilities and reduced energy consumption. Fangli Motors' engineers provided in-depth insights into the design features, technological innovations, and application cases across various industries for this series.

Explosion-Proof Motor Series: Explosion-proof motors are essential power equipment in hazardous environments prone to flammable and explosive substances. Fangli Motors' explosion-proof motor series garnered significant attention at the exhibition, especially from audiences in industries such as coal mining, petrochemicals, and natural gas. Fangli Motors showcased the unique design and safety features of these motors, appealing to safety-conscious professional audiences.

High-Voltage Motor Series: Fangli Electric Motors' high-voltage motor series demonstrated exceptional performance in applications requiring high torque and high power output. These motors are well-suited for various heavy industrial applications, including large machinery equipment and industrial pumps. At the exhibition, Fangli Motors displayed the stability, reliability, and outstanding performance of these motors when dealing with heavy-load tasks.

Interactive Exchange

Throughout the exhibition, attendees were captivated by Fangli Electric Motors' showcased products, prompting them to engage with Fangli Electric Motors' representatives to discuss product technicalities, application cases, and customized requirements. This direct interaction provided Fangli Motors with valuable opportunities to understand market demands and gather feedback. Simultaneously, Fangli Motors demonstrated its exceptional service capabilities through product functionality presentations, combined with customer case studies.

Customer Case Study:

Case Background: A local Indonesian mining company relied heavily on electric motors in its production processes. However, the use of outdated motors resulted in low energy efficiency and significant energy wastage, leading to reduced production efficiency and increased costs.

Objective of Revamp: To achieve efficient energy utilization, decrease energy consumption, and create economic value.

Revamp Solution: 1) Replacing with High-Efficiency Motors: Outdated motors were replaced with high-efficiency motors. These modern motors exhibit lower power losses and higher efficiency, reducing energy consumption under similar operational conditions. 2) Adopting Variable Frequency Control: For motors experiencing variable loads during different time periods, variable frequency drive (VFD) control systems were implemented. These VFDs automatically adjust motor speeds according to the actual load, ensuring the motor operates at optimal efficiency and reducing energy consumption. 3) Motor Management System: An advanced motor management system was introduced to monitor and analyze motor operation in real time. This allows timely problem detection and adjustments, enhancing motor efficiency and lifespan.

Service Achievements: With Fangli Electric Motors' solutions, the customer achieved the expected 50% energy savings rate; annual energy cost savings amounted to 378,000 RMB; the investment in revamping was recovered within 2 years, followed by sustained energy savings benefits for the company.

Looking Ahead

Participation in this exhibition marks a significant step for Fangli Motors in showcasing its innovation capabilities, exceptional quality, and sincere service in Southeast Asia and beyond. The successful involvement in the exhibition not only strengthens Fangli Motors' brand reputation within the industry but also lays a solid foundation for its future development and collaborations. Fangli Motors extends its gratitude to all the visiting partners and attendees and looks forward to achieving greater accomplishments in technological breakthroughs, product innovation, and market expansion in the future.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish