When it comes to the lifespan of an electric motor, the analysis of its operational characteristics reveals that there are two major factors at play: electrical performance and mechanical performance. As long as the components associated with these two aspects of the motor remain trouble-free, the motor can operate and serve its purpose effectively.

First, let's delve into the analysis of the electrical performance of the motor. The electrical performance of a motor is primarily influenced by the balance between the heat generated by the current passing through the windings and the effectiveness of ventilation and heat dissipation. Under normal circumstances, provided that the insulation materials of the motor's windings do not undergo aging, the electrical performance of the motor remains safe and stable. However, in practical operation, factors like voltage instability or overloading can lead to excessive currents, accelerating the aging of the motor's winding insulation and significantly impacting the motor's lifespan. Additionally, vibration issues can also cause instability in the connections within the winding, potentially resulting in circuit faults. Therefore, to ensure the electrical performance of the motor, addressing issues such as voltage instability, overloading, and vibrations is essential for extending the motor's lifespan.

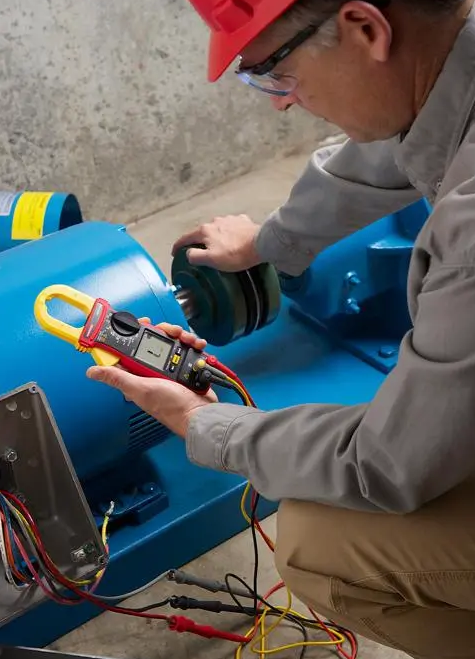

Secondly, mechanical performance is another critical factor to consider. The mechanical performance of a motor is primarily influenced by the quality of the motor's bearing system and the strength of its rotating shaft. As long as regular inspections and maintenance, such as lubrication and timely bearing replacement, are carried out in accordance with the motor's specifications, and as long as the motor's rotating shaft is free from manufacturing or design defects, the motor is safe for operation at its rated capacity. However, in actual operation, issues like poorly designed bearing systems or neglected maintenance can lead to premature mechanical problems in the motor, such as bearing damage or shaft bending. These mechanical performance issues can also reduce the motor's lifespan by causing friction and energy losses.

In summary, the lifespan of an electric motor depends not only on the manufacturing quality of the motor itself but also on its maintenance and usage over time. Regular maintenance and prevention of electrical and mechanical performance issues are crucial for extending the motor's lifespan. Motor manufacturers typically provide a quality assurance period in their product maintenance and usage manuals, but this only covers early-stage quality faults and does not represent the motor's ultimate lifespan. Therefore, motor users should adhere to the manufacturer's maintenance recommendations and pay attention to factors such as voltage stability, overloading, and vibrations to ensure that the motor can operate reliably over an extended period, reducing the risk of failures and prolonging the motor's lifespan.

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Icelandic

Icelandic Indonesian

Indonesian Irish

Irish Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Maltese

Maltese Norwegian

Norwegian Persian

Persian Polish

Polish Romanian

Romanian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Swedish

Swedish Thai

Thai Turkish

Turkish Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh Yiddish

Yiddish